City of Akron History

The City of Akron is located in the industrial Midwest approximately 35 miles south of Cleveland, Ohio. The city covers a total area of 54 square miles and was founded in 1825 by Simon Perkins and Paul Williams. The city was established at the peak development of Ohio during the development of the Ohio and Erie Canal system.

Akron is Ohio’s 5 largest city and is home to 1,200 acres of park and recreational areas within the city limits including the nationally renowned Cuyahoga National Park. Akron is home to performing arts centers, theaters, cultural institutions, and the Akron Zoo, among other things, making Akron an exciting and culturally diverse city to live and work.

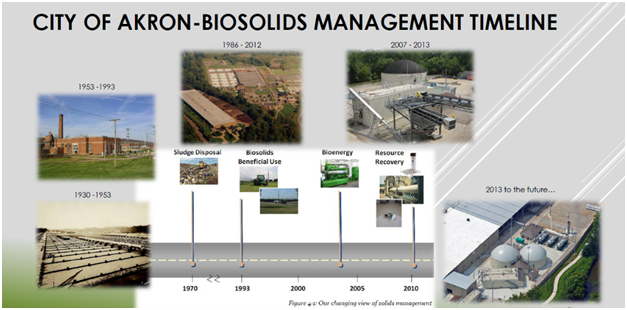

To support the city and the citizens of Akron, the city employs a skilled and talented Public Service Department. Since 1928, the city’s wastewater treatment plant has been in operation, servicing the city and the surrounding communities. The wastewater plant, along with the residuals management component, has come a long way since the late 1920s. Sludge management at the facility has gone through many stages, including disposal and composting, but under the partnership and expertise of KB BioEnergy, it has now found sustainability through anaerobic digestion, energy extraction, and product commoditization.

Kurtz Bros., Inc. General History

Kurtz Bros., Inc. is a family-owned waste-to-resource company headquartered in Cleveland, Ohio. Established in 1948, Kurtz Bros., Inc. has grown from a business that distributed manufactured soil into a multifaceted industry leader in the areas of waste management, construction and demolition debris recycling, bulk material management, landscape supply distribution, industrial by-product beneficial reuse, and storm water and sediment management solutions. Over the past several decades, Kurtz Bros., Inc. has become a pioneer in caring for our environment and natural resources and is committed to the revitalization of our communities. Our mission is to continue to support sustainable initiatives like the innovative waste-to-resource program that we have successfully developed and partnered with the city of Akron.

Kurtz Bros., Inc. Timeline

internal_server_error