To be an industry-leading facility, we depend on industry-leading technology. This is why we’ve invested heavily in the latest equipment and continue to stay focused on the most advanced technology in the marketplace today. Every piece of the anaerobic digestion and residuals management facility in Akron, Ohio was designed to deliver highly efficient, cost-effective results with backup supporting systems throughout the plant. The outcome—a sustainable solution for biosolids management with peace of mind operations that help our customers sleep well at night.

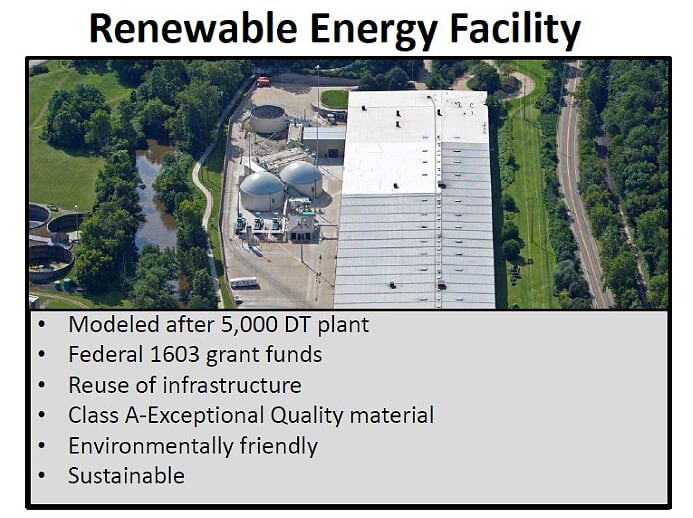

Akron Renewable Energy Facility Overview

The Renewable Energy Facility in Akron, OH is equipped to manage 100% of the city’s biosolids. The facility offers a feed rate of 35,000 gal/day of 5% solids and the digestion process removes 65,000 gal/day of 9% solids and produces 35-45 yds/day of 90% pellet-like material. The central heating and power units (CHPU) produce 30,000 kWh/day.

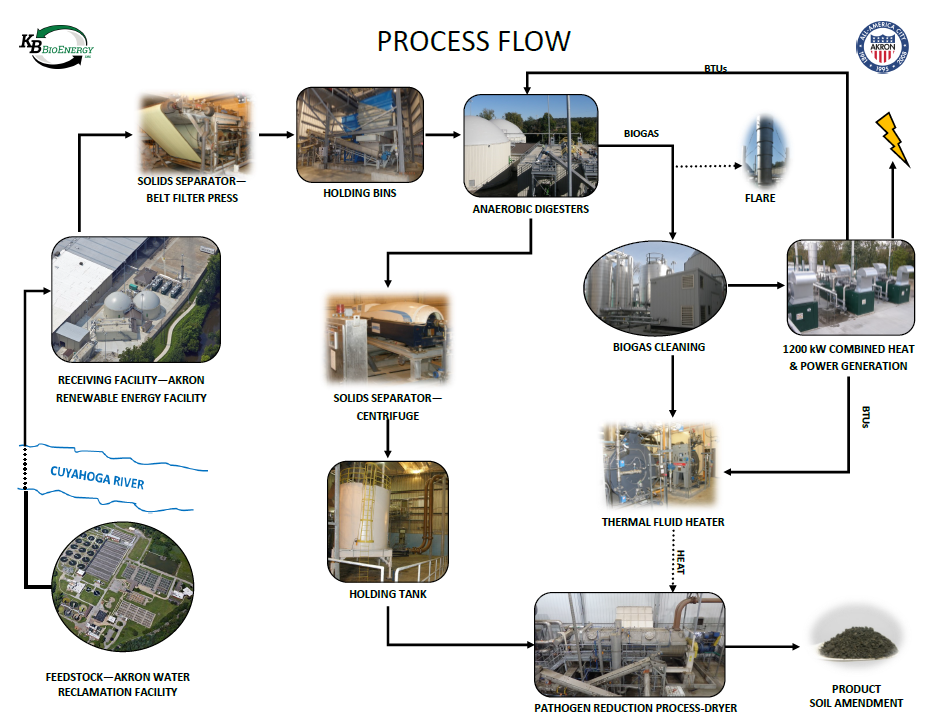

Every component of our advanced process has specialized machinery with specific functions that are integral to the overall facility operation. To better understand the complex system that we operate, please follow our Process Flow map for a stage by stage explanation of the system.

Take a Virtual Tour of Our World Class Biosolids Treatment Facility

Feedstock

Renewable Energy Facility

Our renewable energy facility is environmentally friendly and completely sustainable. We process 35,000 gallons per day of 5% solids feed rate and 65,000 gallons per day of digested solids. In addition to producing Exceptional Quality biosolid, we also generate 30,000 kWh of power at the renewable energy facility.

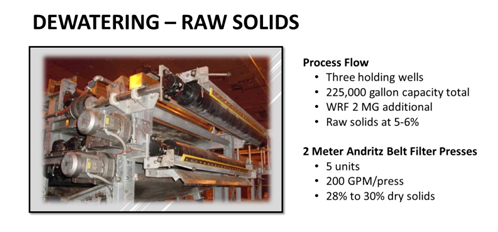

Dewatering

Our five 2-meter Andritz belt presses feature 16 rolls, providing a production capacity of 200 GPM per unit. These presses dewater the raw liquid biosolids from 5% solids to 25% solids “cake” for anaerobic digestion. This dewatered material is conveyed to two holding bins. From the bin conveyors feed the material directly into the EUCO units for digestion.

Anaerobic Digestion

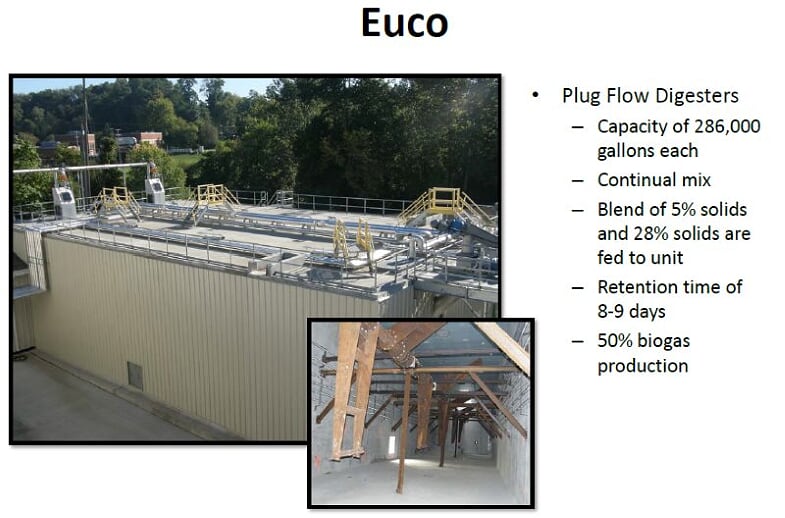

EUCO 1000s

The Renewable Energy Facility features two plug flow digesters that offer liquid capacities of 286,000 gallons each. A blend of 5% solids and 28% solids are fed into the hydrolysis and fermentation reactor. The EUCO 1000s are held at 98°F and the hydrolysis fermentation reactor breaks down the organic compounds and generates biogas.

This machinery has the capacity to handle up to 30% dry solidsandthe ability to process small amounts of septic that are rarely found in the industry. Utilizing this advanced equipment, our system can process 6x the volume of solids processed by other traditional methods.

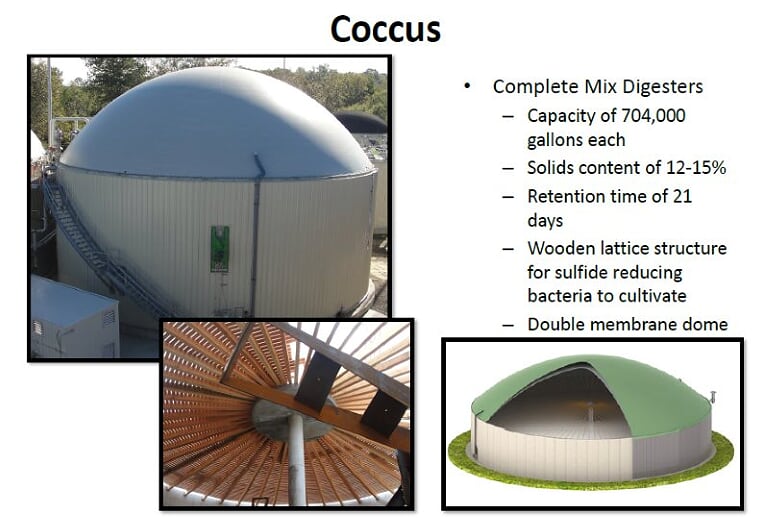

COCCUS

TheCOCCUS 3000s are two complete-mix digesters that offer a liquid capacity of 704,000 gallons each. These circular tanks feature wooden lattice structures under the flexible membrane roofs where sulfide-reducing bacteria cultivate. The double-membrane dome expands and contracts based on biogas production. From here, the biogas that is generated is fed to CHPUs and the dryer.

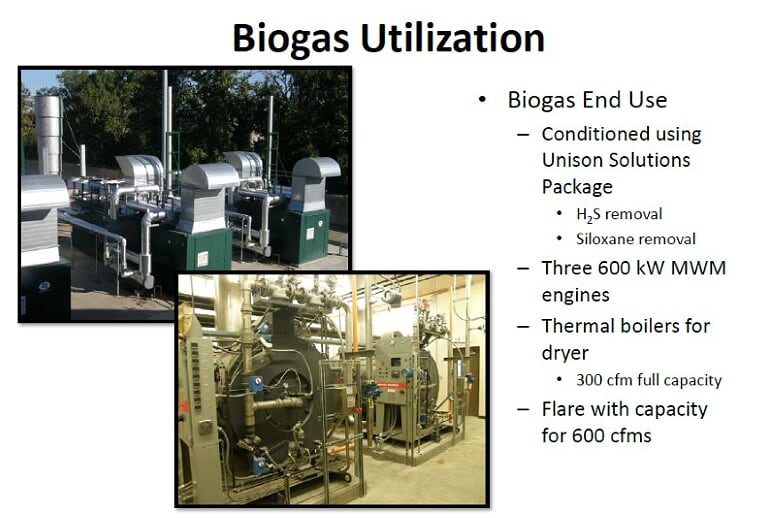

Thermal Output

Three 600kW MWM engines power our central heating and power units. This system features lean combustion technology and an all-in-one package that is connection ready. It offers 41.3% electrical efficiency with a 2.385 MMBTU thermal output. The ADS process generates enough energy to operate the facility and provide a surplus of power that we then route back to the city for their use.

Flare

The flare is used when excess gas cannot be converted into power and instead needs to be flared off. The flare has a capacity of 600 cfms and serves more like a failsafe instead of a routinely operated equipment component.

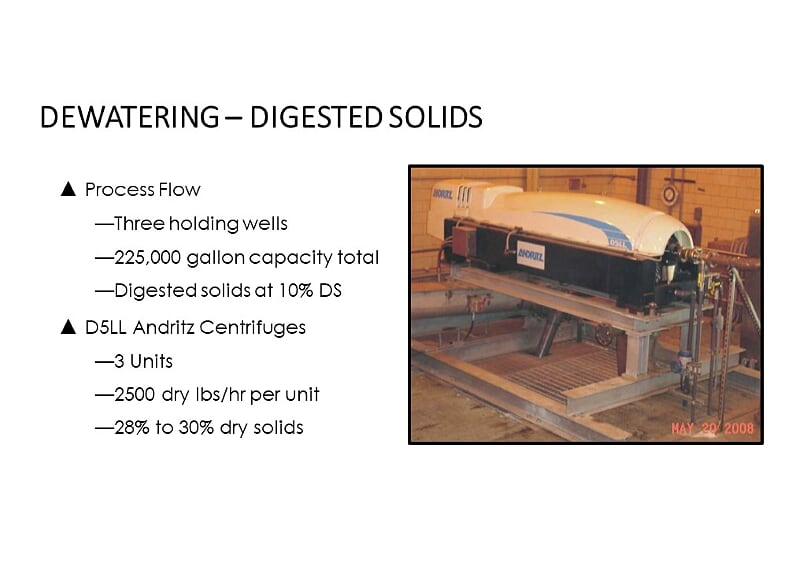

Solids Separation

Filter presses are used to dewater biosolids from the water treatment plant. Dewatering has around 225,000 gallons of capacity and treats raw solids to 28 – 30% dry solids content that is then ready for thermal treatment.

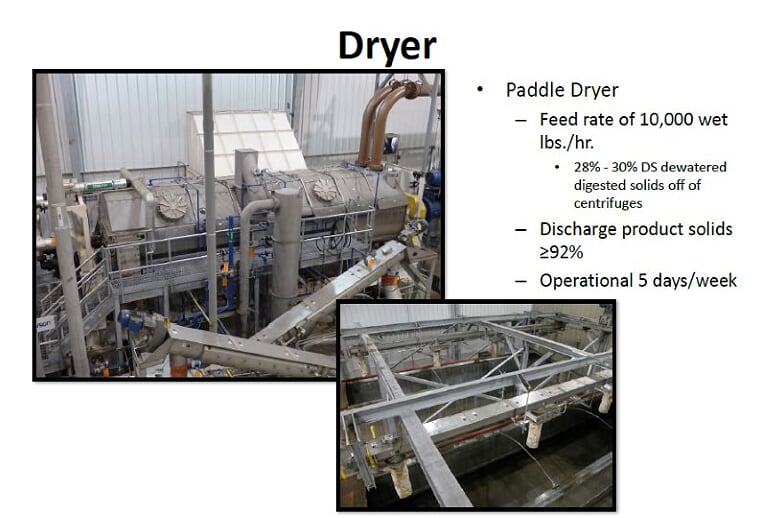

Paddle Dryer

The Renewable Energy Facility’s high-performance dryer is also key to the biosolids treatment process. Our Komline-Sanderson Model 13W-2000 paddle dryer provides 1,974 sq. ft. of heat transfer surface area and 604 cubic feet of working volume.

The machine features two counter-rotation agitator shafts with heated paddles. The feed rate is 10,000 wet lbs./hr. and the evaporation rate is 7,065 lbs. of water/hr. The discharge of product solids is an astonishing 92% solids.

Final Product

After the remaining biosolids are run through the dryer the residual material that is produced represents a dry granular material, packed with nutrients, vital trace minerals, and organic matter that can be used as a soil conditioner or in horticulturalapplications. Approximately 40 cubic yards of materials are produced in 16 hours.

Would you like to find out how KB BioEnergy’s processes could provide better solutions for your municipality or operations? Visit our services page to discover our complete line of waste-to-resource service offerings!